High Power, High Brightness, Lightweight Semiconductor Laser Pump Source

BWT has proposed the theory of dense spatial arrangement (DSBC) and verified the correctness of DSBC through the experiment of kilowatt-level pump source. At present, the power of a single tube has been increased to 15W-30W@BPP≈5-12mm*mrad and the electro-optical efficiency is >60%, which enables the high-power pump source coupled with fiber output to maintain high brightness output while reducing volume, It is possible to reduce the weight and improve the electro-optical conversion efficiency.

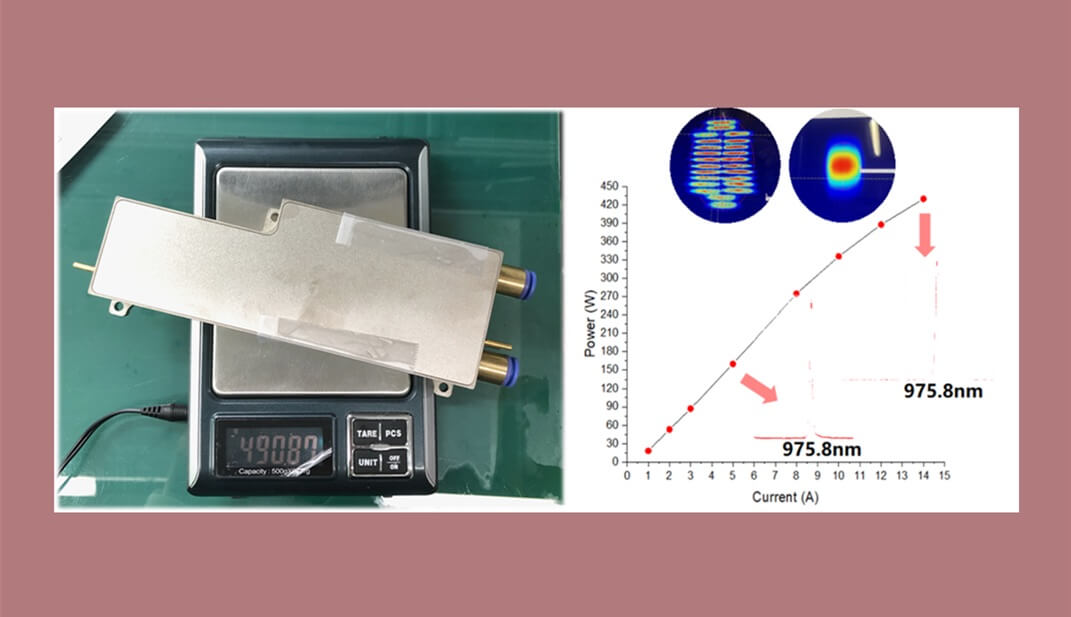

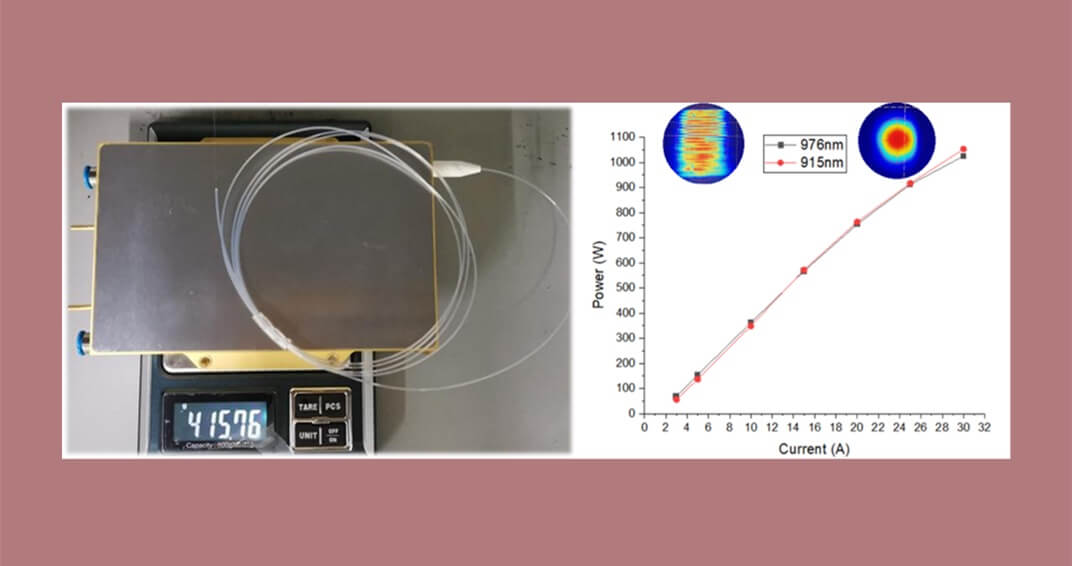

Using the current chip, BWT has respectively realized a pump source with a core diameter of 135μm NA0.22 fiber-coupled output 420W wavelength-locked at 976nm, quality ≈ 500g; and a core diameter of 220μm NA0.22 fiber coupled output 1000W single wavelength 976nm (or 915nm), quality ≈ 400g pump source.

In the future, with the improvement of semiconductor chip brightness and electro-optical efficiency, lightweight and high-power pump sources will play an irreplaceable role in the manufacture of small-volume high-power fiber laser light sources, and will actively promote the development of industrial applications.

Introduction

Fiber lasers have grown rapidly due to their excellent beam quality and flexible power expansion capabilities (fiber combiners). In recent years, single-mode single-fiber fiber lasers are limited by TMI (transverse mode instability) and SRS effects, and the power of semiconductor direct pumping fiber laser oscillators is limited to 5kW [1]. The laser amplifier is also stopped at 10kW[2]. Although the output power can be increased by appropriately increasing the core diameter, the output beam quality also decreases -1. Nevertheless, the demand for improving the brightness of semiconductor pump sources is still urgent.

The relationship between the semiconductor chip BPP and the brightness of the pump source

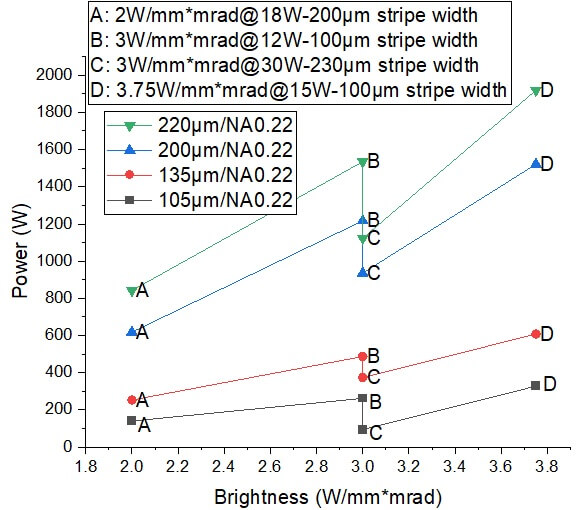

Three years ago, the brightness of 9xxnm chips was mostly at the level of 3W/mm*mrad@12W-100μm strip width & 2W/mm*mrad@18W-200μm strip width. Based on such chips, BWT achieves 600W and 1000W 200μm NA0.22 fiber-coupled output-1.

At present, the brightness of 9xxnm chips has achieved 3.75W/mm*mrad@15W-100μm strip width & 3W/mm*mrad@30W-230μm strip width, and the electro-optical efficiency is basically maintained at around 60%.

According to the theory of dense spatial arrangement [6], it is calculated according to the average fiber coupling efficiency of 78% (laser emission from the chip to fiber coupling output: single-wavelength spatial beam combining and polarization beam combining without VBG), and it is assumed that the chip works at the highest power ( The chip BPP is different at different currents), we have compiled a data map as follows:

It can be found from the above figure that when a certain fiber (core diameter and NA is fixed) achieves a specific power coupling output, for chips with different brightness, the number of chips is different, and the volume and weight of the pump source are also different. For the pumping requirements of the fiber laser, if the pump source made of the above chips with different brightness is selected, the weight and volume of the fiber laser of the same power are completely different, and the configuration of the water cooling system is also quite different.

High efficiency, small size and light weight are the inevitable trends in the development of future laser light sources (whether diode lasers, solid-state lasers or fiber lasers), and the brightness, efficiency and power of semiconductor chips play a decisive role in it.

In order to adapt to the fiber combiner, we selected common fiber specifications: 135μm NA0.22 and 220μm NA0.22. The optical design of the two pump sources adopts dense spatial arrangement and polarization beam combining.

Among them, the 420WLD adopts 3.75W/mm*mrad@15W chip and 135μm NA0.22 fiber, and has VBG wavelength locking, which meets the requirements of 30-100% power wave locking, and the electro-optical efficiency is 41%. The LD body is made of aluminum alloy material and sandwich structure [5]. The upper and lower chips share the water cooling channel, which improves the space utilization. The light spot arrangement, spectrum and power output (power in the fiber) are shown in the figure:

The 1000WLD adopts a 3W/mm*mrad@30W chip and a 220μm NA0.22 fiber, which achieves 915nm and 976nm fiber-coupled output of 1000W respectively, and the electro-optical efficiency is >44%. The LD body is also made of aluminum alloy material. In order to pursue a higher power-to-mass ratio, the LD shell has been simplified under the condition of ensuring the structural strength. The LD quality, spot arrangement and output power (power in the fiber) are as follows :

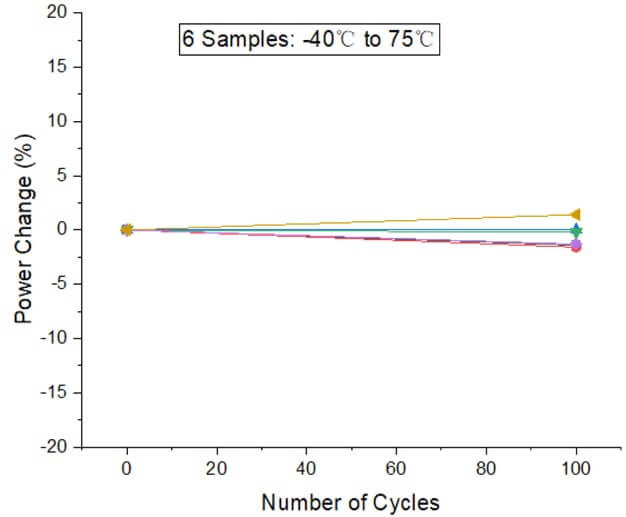

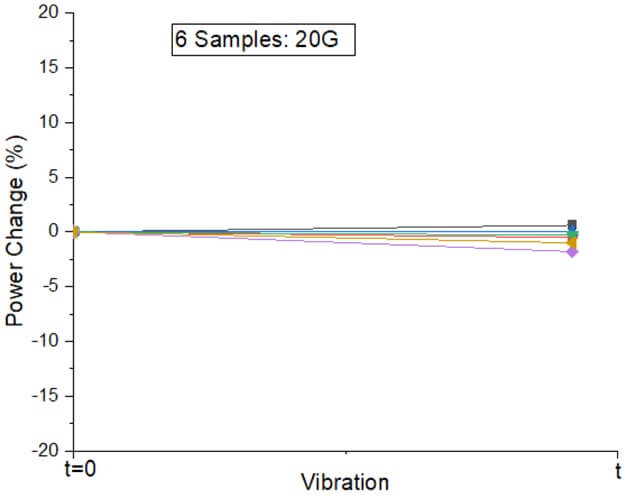

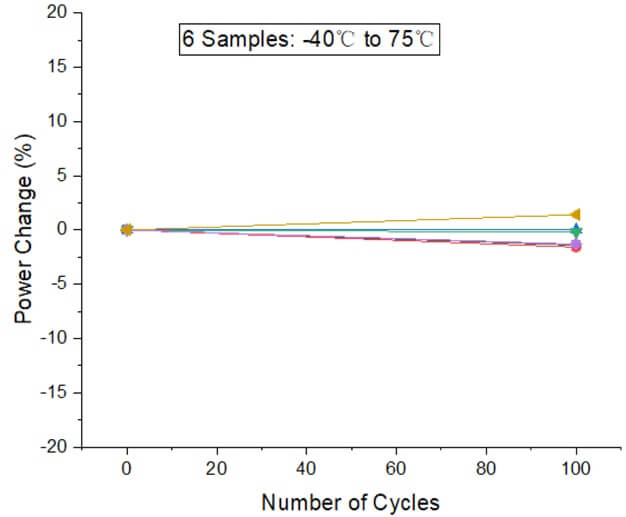

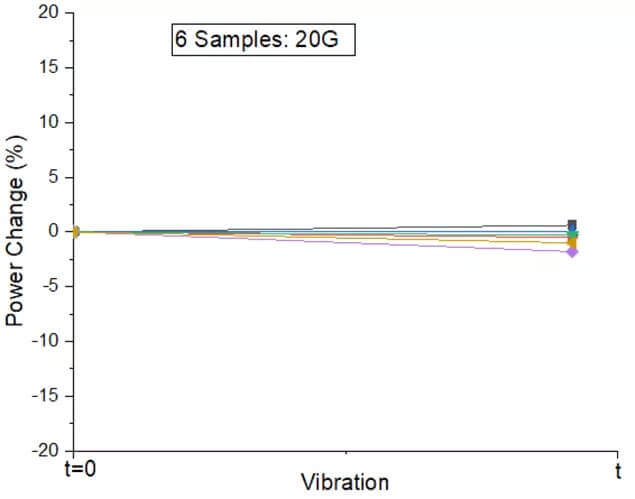

In order to improve the reliability of the pump source, the coupling end fiber adopts quartz end cap fusion and cladding light filtering technology, which makes the temperature of the fiber outside the pump source near room temperature. Six 976nmLDs were selected for high and low temperature shock and vibration tests. The test results are as follows:

*High and low temperature impact test

Conclusion

Achieving high brightness output comes at the expense of electro-optical efficiency, that is, the highest output power and the highest electro-optical efficiency cannot be obtained at the same time, which is determined by the chip brightness and the normalized frequency of the coupling fiber. In the multi-single-tube spatial beam combining technology, brightness and efficiency are always the goals that cannot be achieved at the same time. The balance of electro-optical efficiency and power should be determined according to the specific application.

References

[1] Mller Friedrich, Krmer Ria G., Matzdorf Christian, et al, “Multi-kW performance analysis of Yb-doped monolithic single-mode amplifier and oscillator setup,” Fiber Lasers XVI: Technology and Systems (2019).

[2] Gapontsev V, Fomin V, Ferin A, et al, “Diffraction Limited Ultra-High-Power Fiber Lasers,” Advanced Solid-state Photonics (2010).

[3] Haoxing Lin, Li Ni, Kun Peng, et al, “China's domestically produced YDF doped fiber laser achieved 20kW output from a single fiber,” Chinese Journal of Lasers, 48(09),(2021).

[4] Cong Gao, Jiangyun Dai, Fengyun Li, et al, “Homemade 10-kW Ytterbium-Doped Aluminophosphosilicate Fiber for Tandem Pumping,” Chinese Journal of Lasers, 47(3), (2020).

[5] Dan Xu, Zhijie Guo, Tujia Zhang, et al, "600 W high brightness diode laser pumping source," Spie Laser,1008603,(2017).

[6] Dan Xu, Zhijie Guo, Di Ma, et al, "High brightness KW-class direct diode laser," High-power Diode Laser Technology XVI, High-Power Diode Laser Technology XVI, (2018).