New energy processing

Laser technology supports processing in new energy fields such as photovoltaic cells, driving energy technology advancements, promoting the transition to clean energy, and fostering a green circular economy for electricity. It plays a crucial role in achieving carbon peaking and carbon neutrality goals.

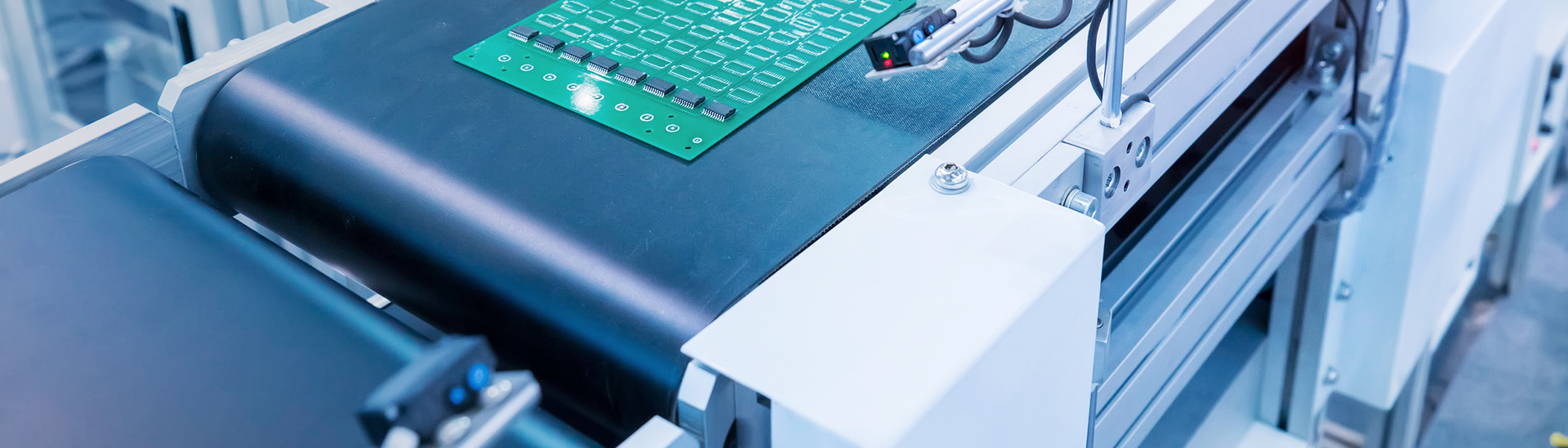

Electronic circuit processing

Picosecond ultraviolet and green laser products find widespread applications in the field of electronic circuit processing, such as PCB, FPC, PET, and PI. They enable micron-scale processing and excel in shaping irregular forms. Additionally, they are the ideal processing tools for various types of film materials.

Processing of hard and brittle materials

Glass, ceramics, sapphire, diamond, silicon, and other hard and brittle materials require higher-quality processing than traditional methods can provide. The development of ultrafast laser technology will further expand the application fields of hard and brittle materials. Compared to conventional processing methods, ultrafast lasers demonstrate superior performance in processing precision, surface quality, and edge quality.

Display panel processing

LCD, OLED, MiniLED, and other display panels are increasingly widespread, with narrower line widths. The "cold processing" characteristics of ultrafast lasers can prevent thermal damage to materials and meet the growing demands for precision processing. As a result, ultrafast lasers are extensively used in processes such as the delamination and shaping of OLED glass substrates, irregular cutting of LCD panels, and cutting of MiniLEDs.

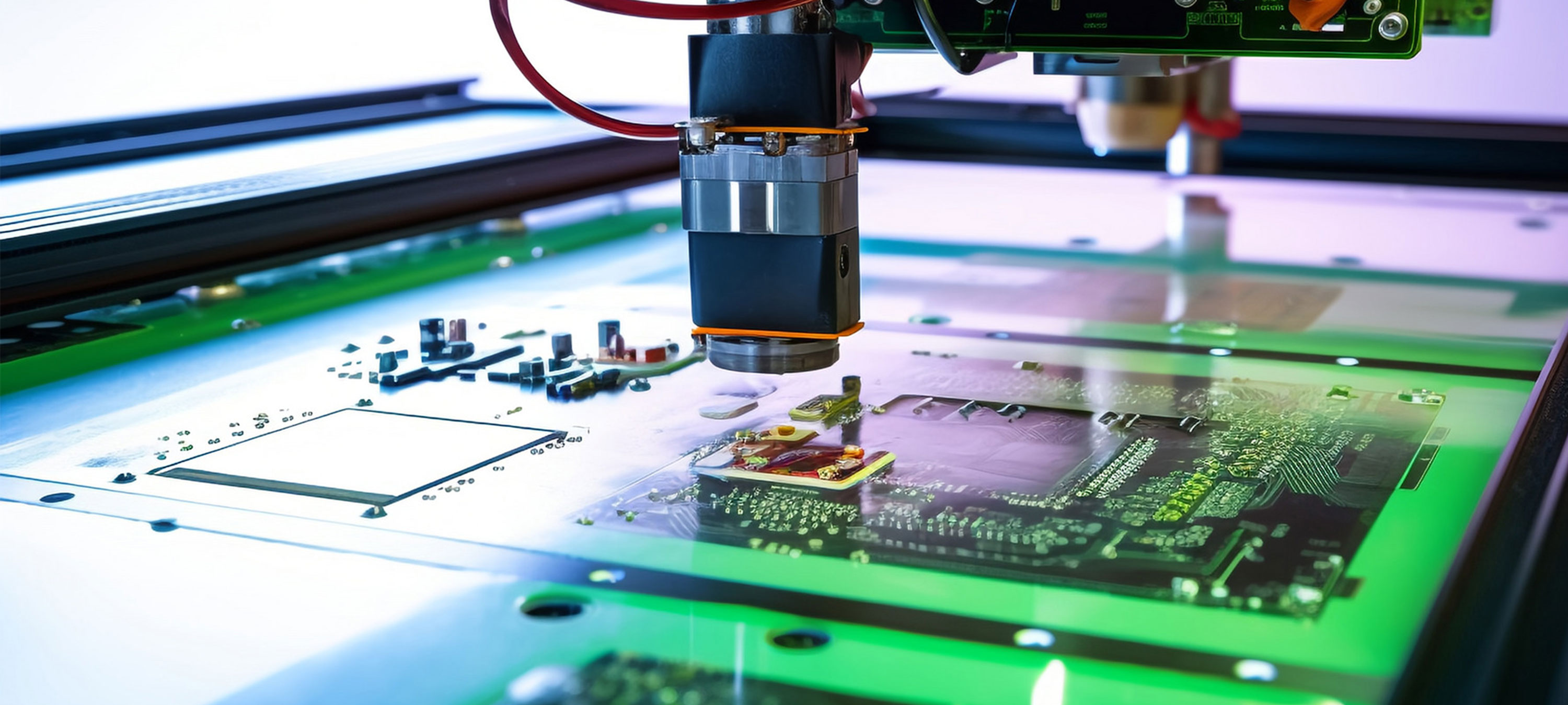

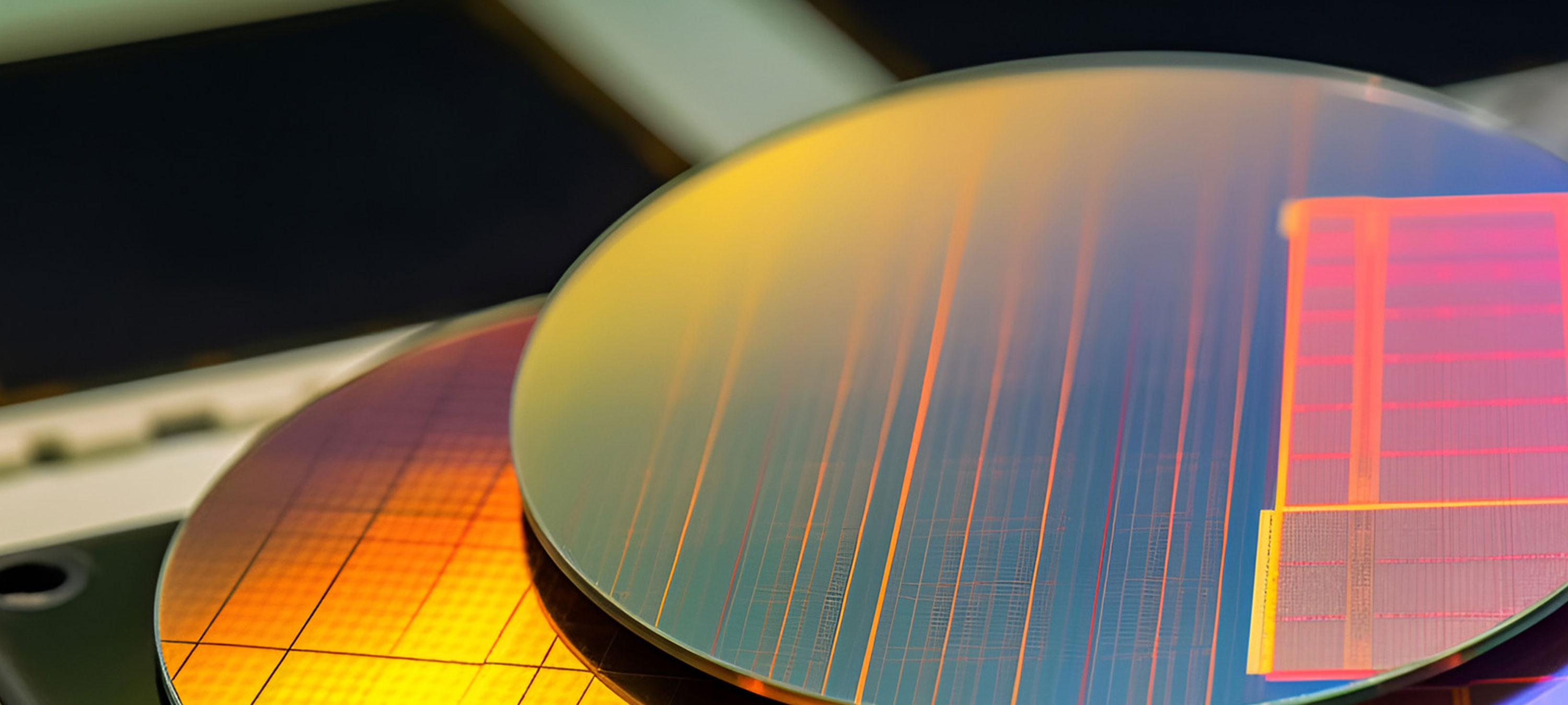

Semiconductor processing

Ultrafast laser cutting technology offers numerous advantages in the field of semiconductor processing, including high cutting efficiency, dust-free operation, no material loss, and a fully dry process. As a result, it has become indispensable in semiconductor wafer dicing.

Laser surface treatment

Ultrafast lasers, with their short pulse duration, high peak power, and extremely low thermal impact, enable precise marking and engraving on various materials. This includes features such as creating black barcodes inside glass without damage, invisible QR codes within glass, hidden QR codes on high-end precision circuit boards, film removal from solar cells, ITO coating etching, and precise marking and engraving on metal materials, among other precision processing applications.