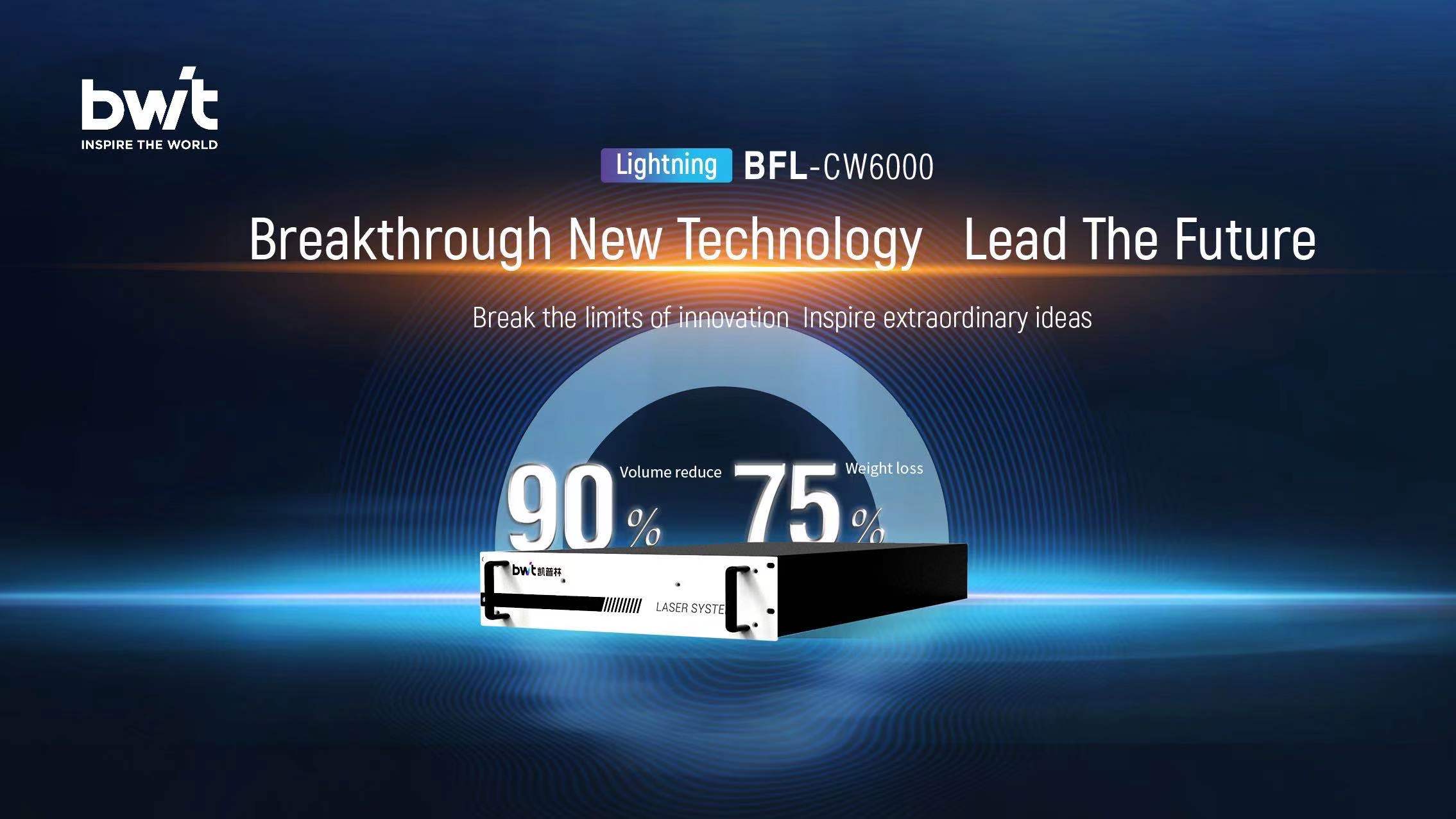

BWT launches Lightning 6000W fiber laser | Smaller, lighter and smarter

Let me introduce, I am Lightning series BFL-CW6000 fiber laser. Yes, today is my show.

Follow our friends, you should be familiar with the Lightning family. Previously, we successively launched three power fiber lasers of Lightning series BFL-CW3000/2000/1500. If the volume change of these three models before and after the upgrade is the difference between goose eggs and eggs, then the power of 6000W is the change from ostrich eggs to quail eggs. - This analogy is a bit exaggerated.

However, the Lightning 6000 is indeed an amazing volume change (how amazing? I will talk about it later), and it is smaller and lighter than similar products in the market, reaching a leading level among similar products in the world.

To say who is in charge of the C position in the near future, it must be the Lightning series BFL-CW6000 fiber laser.

Compared with the 6000W beam-combined fiber laser, the volume of the Lightning series BFL-CW6000 fiber laser is reduced by nearly 90%; the weight is reduced by nearly 75%; the optical path and water path design are more reasonable, comprehensively improve the heat dissipation efficiency, and ensure high-quality optical output quality .

Facing the application requirements of ultra-high-power fiber lasers in the future, Lightning series products effectively solve the defects of volume redundancy, bulkiness, unstable output power, power attenuation, and module easy damage after the ultra-high-power fiber lasers are combined.

Small size is the most intuitive feature of Lightning series BFL-CW6000 fiber laser. In addition, it has the following advantages:

1. Using the fourth-generation pump source technology, the photoelectric conversion efficiency of the whole machine is as high as 40% or more.

2. Stable and reliable forced water circulation thermal control management scheme and optimized cooling system design.

3. The selection of high-quality electronic components ensures the high reliability of the driving and control of the laser.

4. Adopt anti-high-reflection structure design, high-power fiber laser stripper technology, and unique water-cooling structure, which can effectively eliminate more than 80% of the return light.

5. Access to IoT technology to realize real-time monitoring and fault warning of equipment status.

6. Bluetooth centralized control function, online monitoring of laser operating status, working parameters and alarm information.